Test bench for cut protection materials

Customer: University of Applied Forest Sciences Rottenburg

Area: Material Research Institute

Requirements: Test bench for testing cut protection materials

Implementation: Hardware: Digital I/O module NI USB-6509, multi-function data acquisition device NI USB-6212 / software: LabVIEW

Protective clothing saves lives

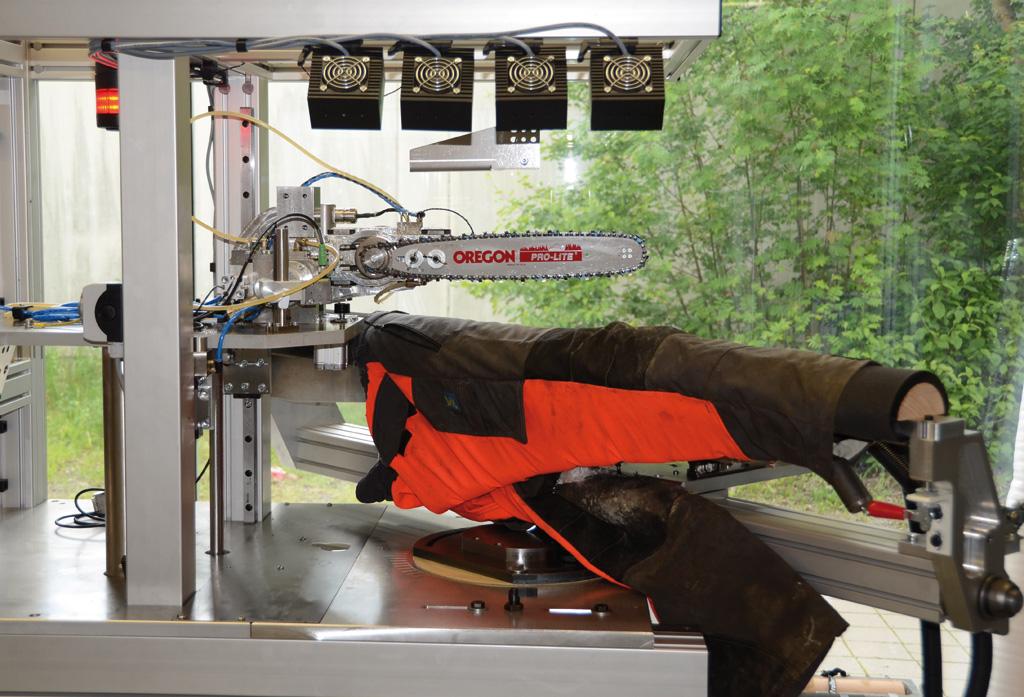

Working with motorized chain saws poses significant dangers. In cooperation with the University of Applied Forest Sciences Rottenburg, measX developed an innovative test bench for the evaluation of cut protection clothing. The goal is to optimize the protective materials.

“The clothes make the person,” as everyone knows. In private life, jackets, slacks and other articles of clothing play a key role in expressing the wearer’s own personality. At work, the focus lies on functional aspects. Proper clothing protects against undesired external influences, lowers the risk of accidents and, in extreme cases, can even save lives. This is true, for example, in the field of forestry, where powerful motorized chainsaws are frequently used. Despite compliance with all safety precautions and the fact that wearing cut protection clothing is mandatory during forestry work, severe and sometimes life-threatening accidents repeatedly occur. “Inattention during operation or unexpected, powerful jolts in the motorized saws can result in contact between the saw chain and a person. It is critical in such cases that the cut protection material brings the saw chain to a stop as quickly as possible,” explains Dr. Dirk Wolff, Professor of Forestry Work and Forestry Technology at the University of Applied Forest Sciences Rottenburg. A special test bench was developed here for testing the quality of cut protection materials and evaluating them according to established guidelines and standards. The control software for this test bench comes from measX.

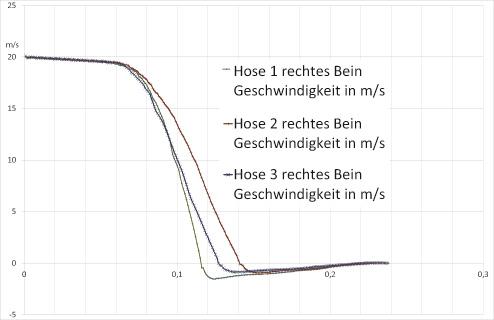

A material that stops chain saws

The functioning principle of cut protection materials is simple: Upon contact with the saw chain, long fibers from the protective material become tangled in the drive pinion, thereby jamming the chain saw. The test bench is used to investigate how long it takes the material to bring the saw chain to a stop. Because the deceleration time of the saw chain depends significantly on the chain tension, an automatic calibration takes place before the actual test run. The motorized chain saw is brought to a defined speed and switched off after a brief warm-up. It is then automatically tensioned or relaxed until the chain deceleration time matches the specified target value. After this calibration process, the test begins, such as on a pair of cut protection slacks: The motorized saw chain is brought back up to the desired speed and then switched off. At the same time, a pin is released so that the saw falls onto the pair of cut protection slacks. The test bench records all relevant values and measures the time until the chain comes to a stop.

Individual software solution

The test bench is operated via a graphical user interface on a central test bench computer. The test bench software developed on the basis of LabVIEW handles all control tasks, measures the relevant signals and directly evaluates them. “The measurement data for the chain deceleration time and the course of the fall is saved in a measurement value archive and can be loaded again at any time for subsequent analysis,” explains measX project supervisor Dennis Esche. Various environmental parameters, such as position and temperature, are also recorded. The test bench also controls a high-speed camera that films the entire test sequence at 2,000 frames per second.

The data communication for control and data acquisition takes place via two USB modules from National Instruments. The digital I/O module NI USB-6509 handles the majority of the test bench control. The multi-function data acquisition device NI USB-6212 handles the other control tasks and records the analog measurement data. The chain deceleration time and the course of the fall are measured via two counter inputs.

Improving safety standards

Improving safety standards

The cut protection test bench is not used only for university research purposes; material tests are also carried out for manufacturers of cut protection material. “With our tests, the quality of protective clothing can be evaluated objectively and then consistently improved on this basis. This has a positive impact on the safety standard in forestry work, for example,” says Prof. Dirk Wolff of the University for Applied Forest Science.