eGAS – electronic Gas Analysis System

Mobile Test Rig for lead-acid batteries

Side reactions in modern lead-acid batteries are complex especially under dynamic conditions. But knowing about the behavior and condition of the battery is very important in the development of lead acid batteries for today‘s vehicles with start-stop systems micro-hybrid solutions.

Side reactions in modern lead-acid batteries are complex especially under dynamic conditions. But knowing about the behavior and condition of the battery is very important in the development of lead acid batteries for today‘s vehicles with start-stop systems micro-hybrid solutions.

measX now offers a new portable method for rapid measurement of water loss in advanced lead batteries.

Current measurement of water loss

Advanced lead batteries (EFB and AGM) have far superior Dynamic Charge Acceptance (DCA) compared to lead batteries of the past. However, a side effect of the improved DCA is the observed accelerated water loss at high temperature due to hydrogen evolution.

This needs to be measured quantitatively by weight (g/Ah) (with a precise balance) or by volume (ml/minute) and gas composition (% hydrogen, oxygen, carbon dioxide-using a specialised device such as the measX eGAS) to understand the processes.

The weight change measurements is the most common method but it is imprecise and lacks time resolution.

The volumetric measurement is available but not widely used and limited to the laboratory.

As third option gassing rate and gas composition evaluation techniques are used but they are complicated, time consuming, and only available in specific R&D laboratories and can’t be used for field measurements.

Figure 1: Sensor line

Figure 1: Sensor line

The eGas Solution

In-situ real-time measurement of gas flow and composition is straightforward with modern sensors. (Figure 1). They can accurately detect the amount of produced gas.

Compact and portable

eGAS provides a unique solution for measuring water loss in high DCA lead batteries as a portable, compact and inexpensive device. In-situ measurement of water loss and evolved gas composition now can be conducted both in field and in the laboratory.

eGAS will have revolutionary impact on quantity and quality of collected battery failure data.

Developed by Experts

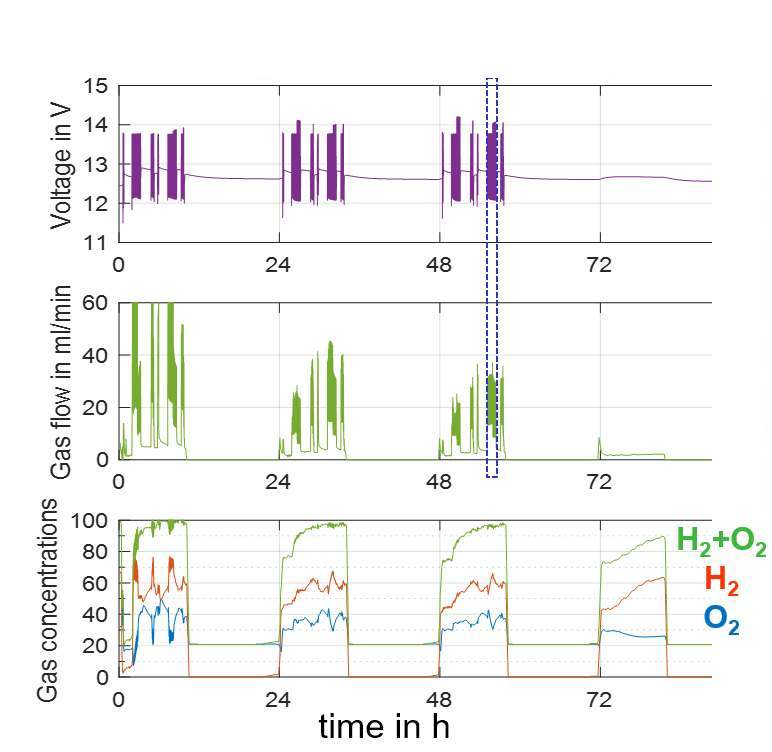

Figure 2: Gas floweGAS has been developed by measX through extensive collaboration with European car companies and co-funded by the Advanced Lead–Acid Battery Consortium (ALABC).

Figure 2: Gas floweGAS has been developed by measX through extensive collaboration with European car companies and co-funded by the Advanced Lead–Acid Battery Consortium (ALABC).

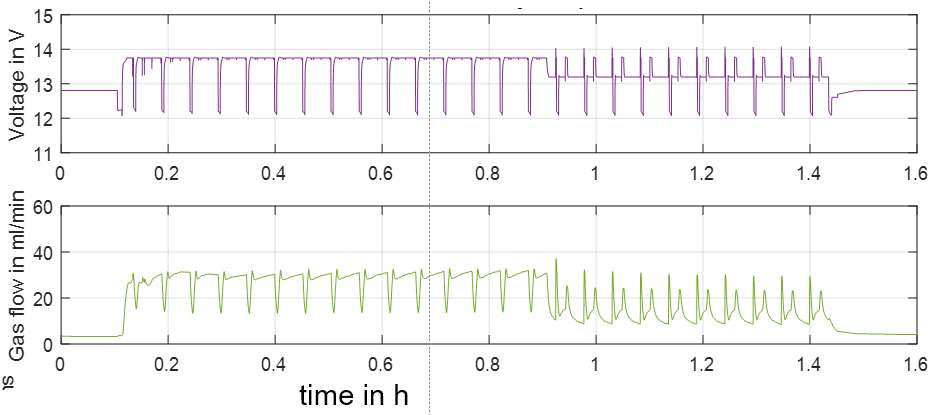

Figure 2a: Gas flow (slice of Fig. 2)

Figure 2a: Gas flow (slice of Fig. 2)

The system is designed for flexible standalone operation in a laboratory or a vehicle and will record gas flow rates (up to 100 ml/min), concentrations of hydrogen, oxygen, and carbon-dioxide, along with battery voltage and temperature as well as ambient pressure and temperature. It is recommended for all investigations of side reactions in EFB and EFB+C, for example Tafel characterization, water consumption/gasing under laboratory or driving conditions, oxygen cycle in flooded and valve-regulated systems, as well as selection of additives for high DCA. Additional parameters such as battery voltage and temperature are also logged by the system.

Figure 2 and 2a show examples of gas flow collected from urban drive cycle and technical specifications of the system.

| Technical data eGAS device | |

|---|---|

| Gas Sensors: |

Pewatron O2 PO2ES-103P |

| Flowmeter: | Bronkhorst F-101D-AGD-00-V |

| Temperature sensors: | 2 temperature sensors (internal and at battery) |

| Voltage: | battery voltage sense tightness test adapter |

| Data Acquisition: | Micro Controller with SD card and USB |

| Data Interface: | USB |

| Software: | windows-based, developed by measX |

| Dimensions: | 27 x 18 x 14.5 cm |

| Weight: | 4,2 kg |

| Others: | 2,8 inch TFT-display, AC power supply, DC (12V) connection external battery with loader, seaworthy carrying case |

Powered by ALABC ![]()

Scientific study at "Science direct": Study on water electrolysis mechanism of a lead-acid battery under idling stop system operational conditions