Custom test bench modernization for long-term, efficient operation

In the face of ever shorter production and product life cycles as well as continuously changing safety requirements and environmental standards, measurement and testing systems must be constantly adapted. For example, new product generations require different, often significantly more complex test procedures.

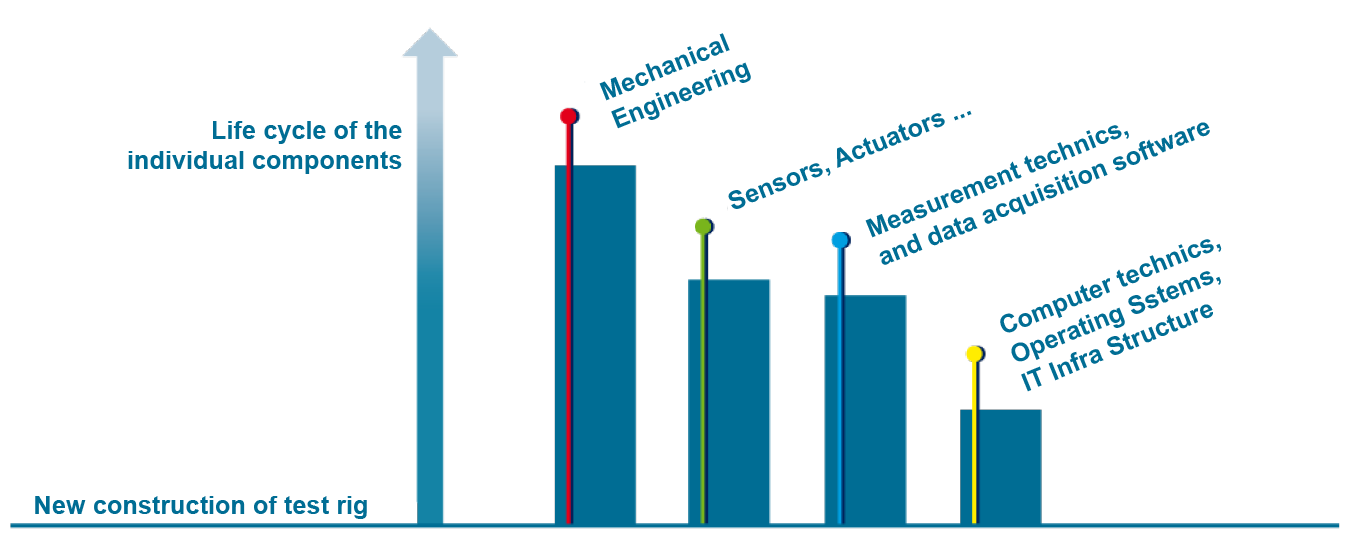

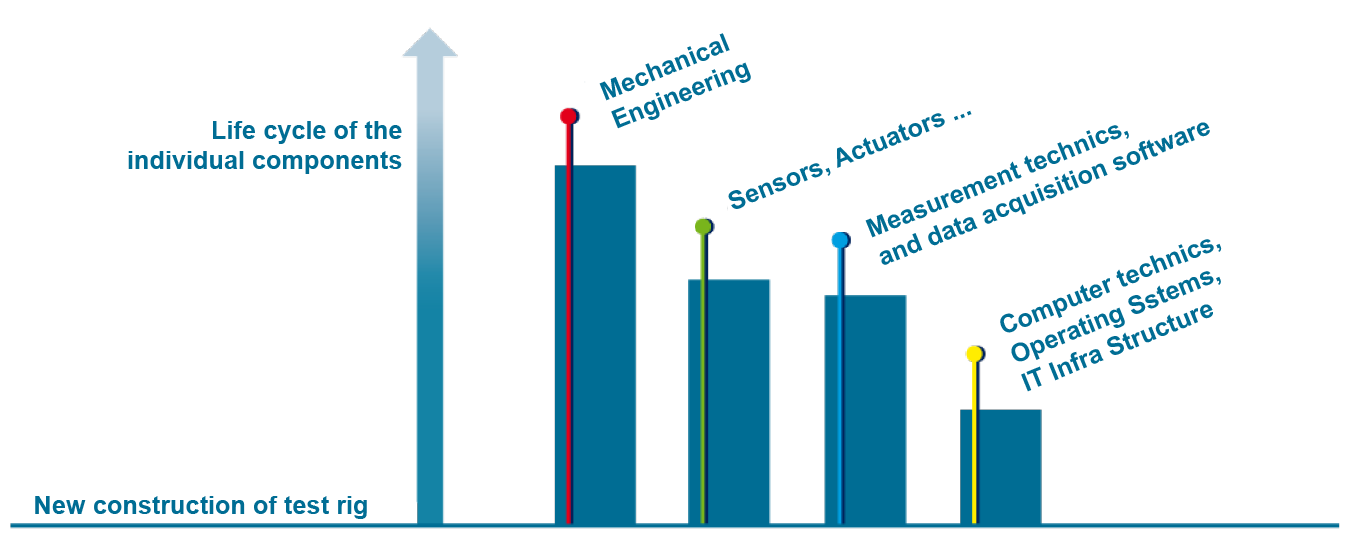

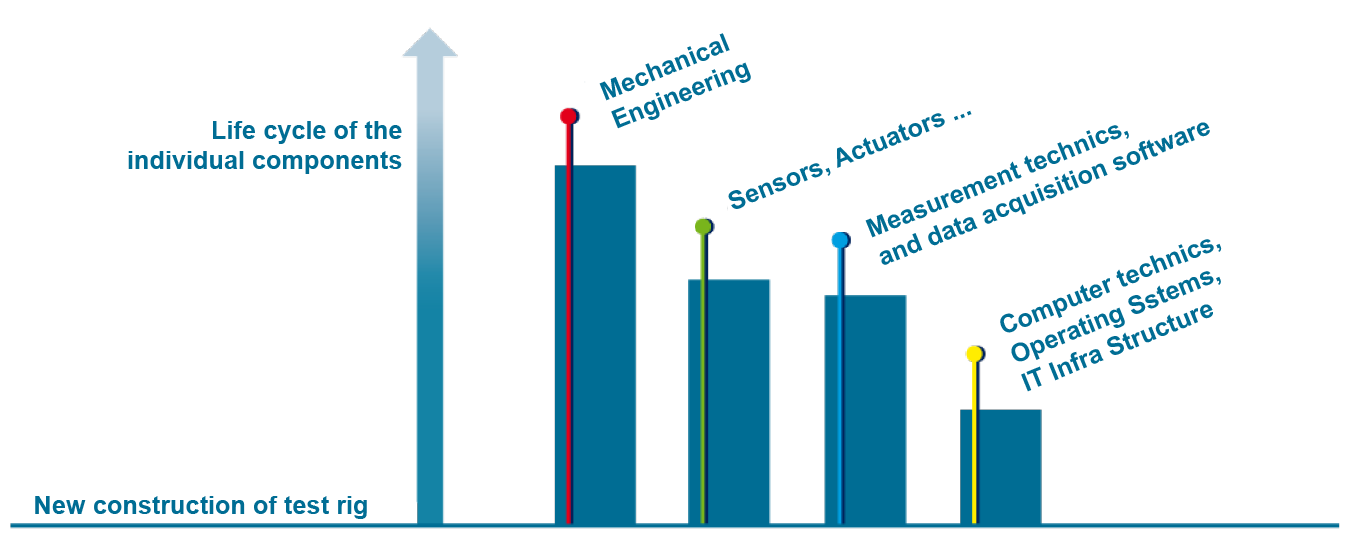

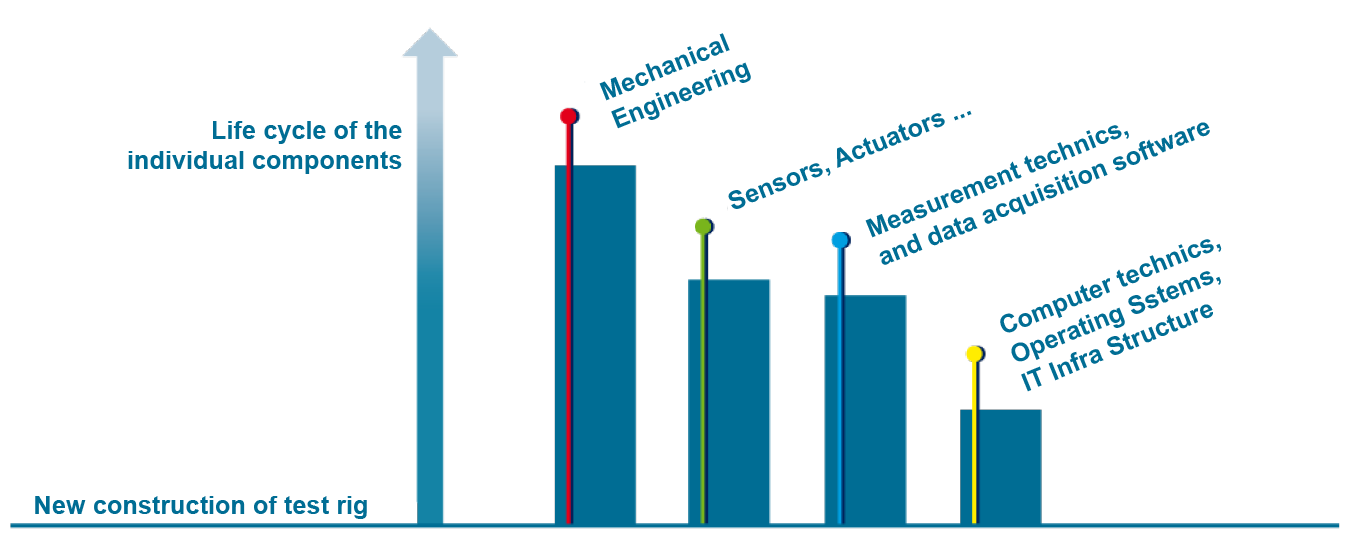

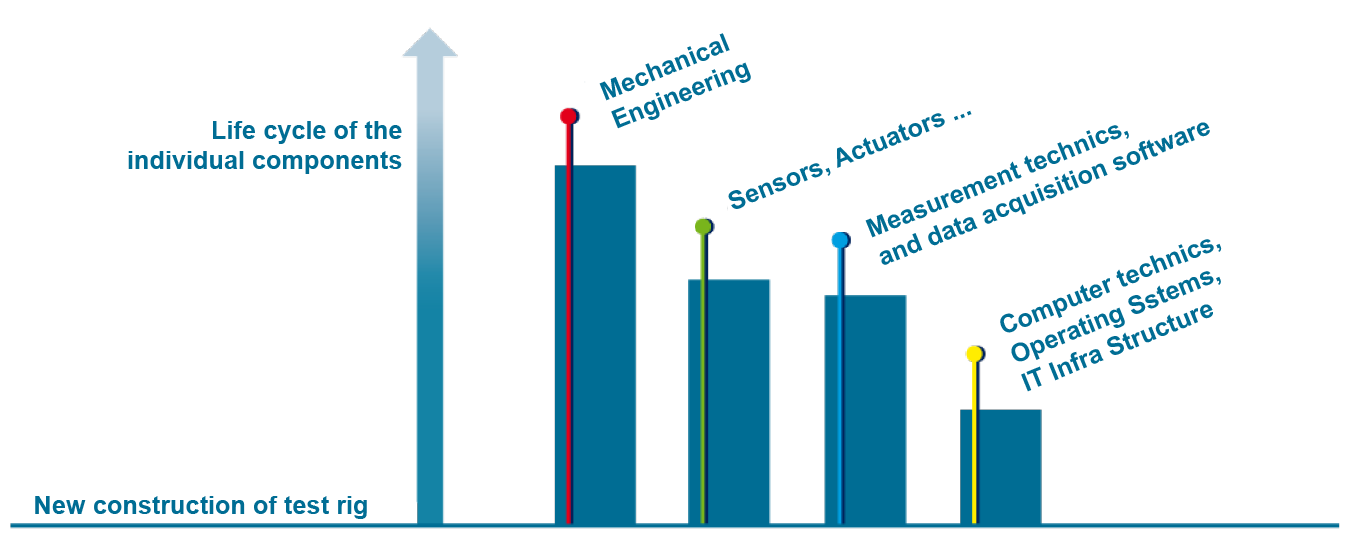

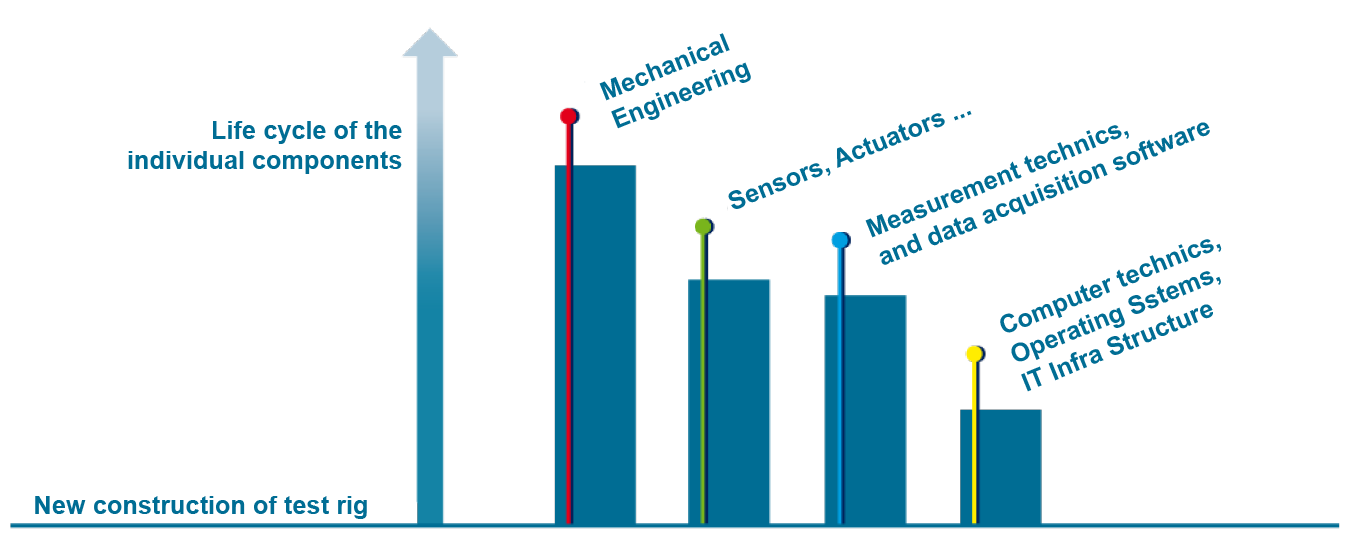

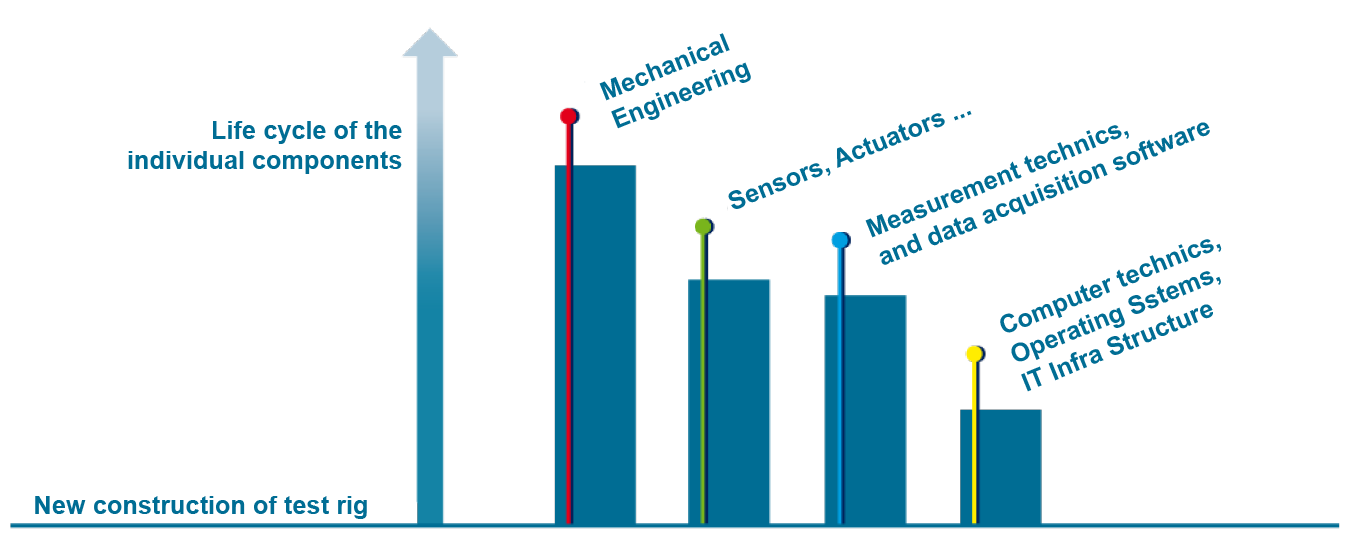

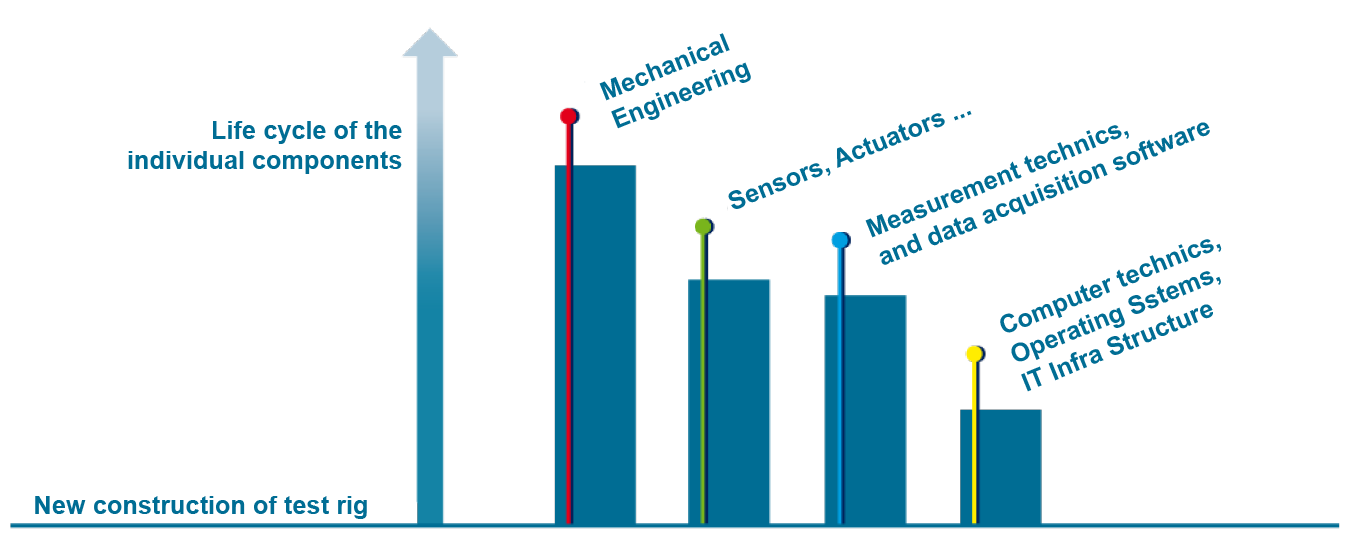

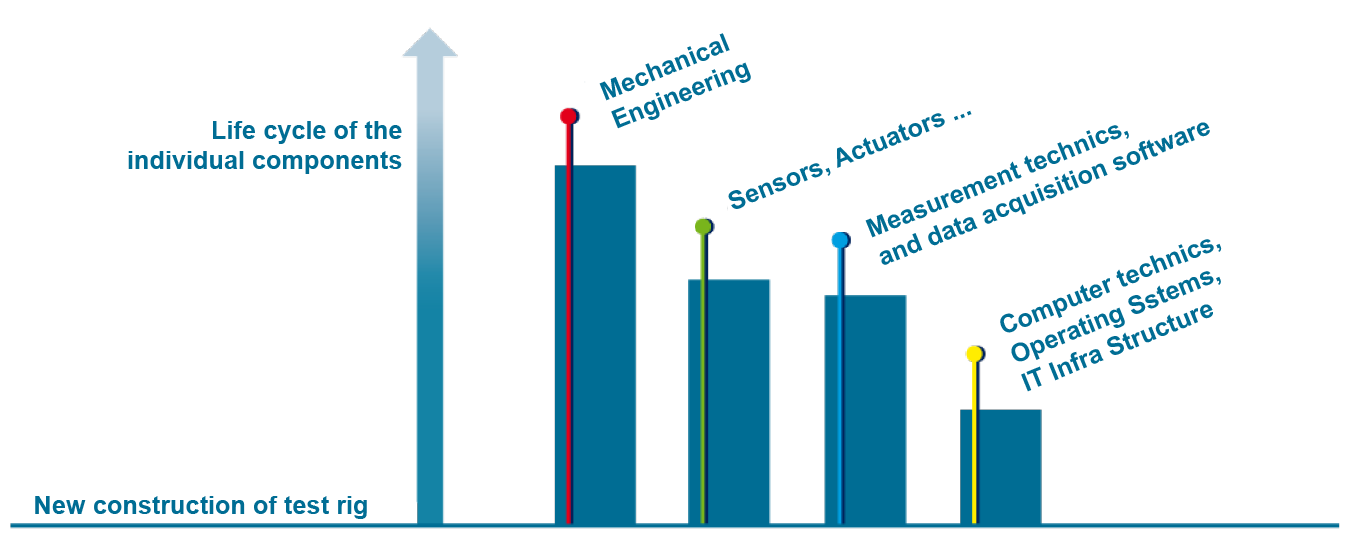

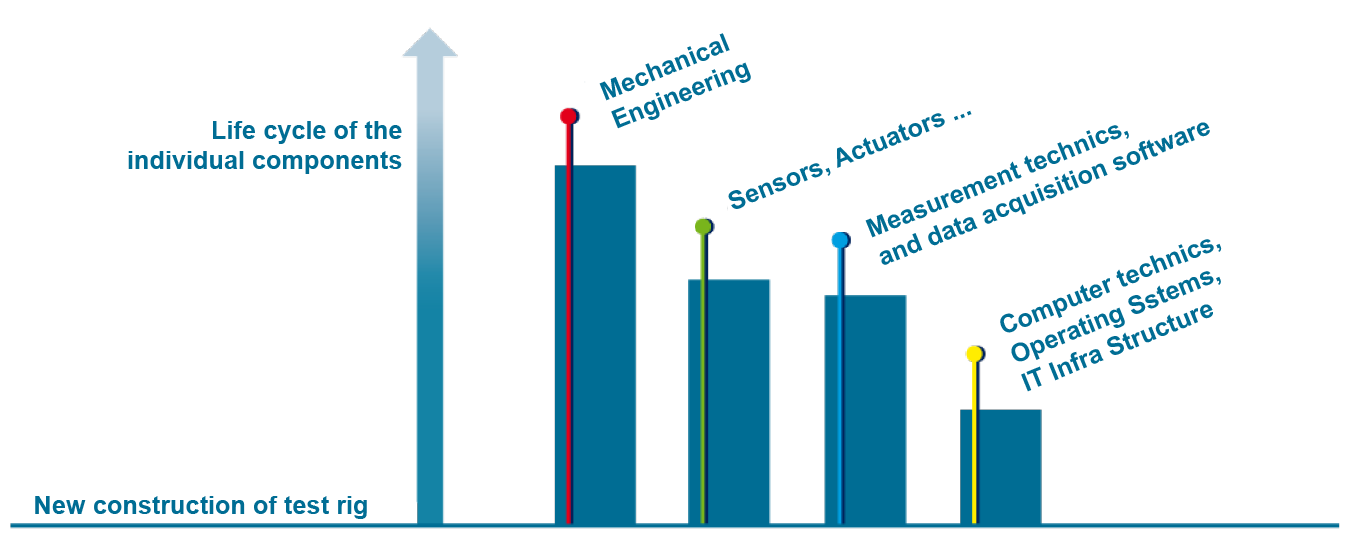

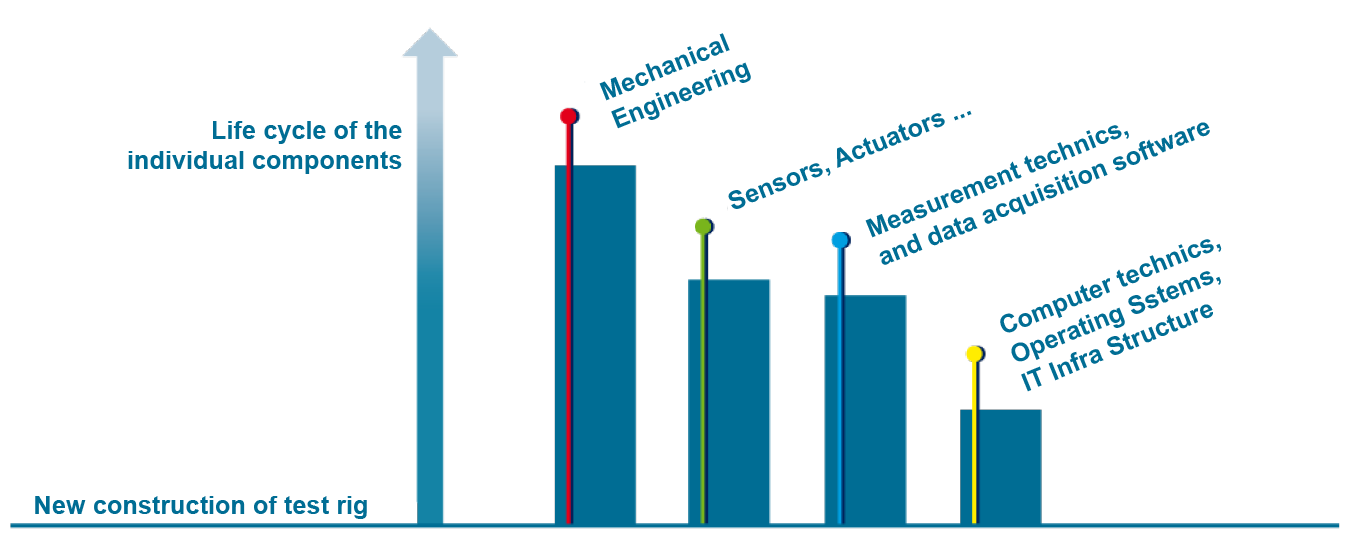

Depending on the modernization objective, however, test systems do not need to be completely rebuilt. This is because the lifespans of the individual components differ widely: It is not rare for the computer technology and data acquisition to require urgent replacement while the automation components, hydraulics and electrical systems require no modernization.

measX is a specialist in individual modernization concepts: First, the requirements on the modernization are carefully analyzed. On this basis, we develop a recommendation that perfectly addresses all the requirements and takes future developments into account as well as possible.

With intelligent modernization, you can optimize the quality of your measurement and testing processes.

Your benefits:

- Competitiveness: Carry out testing tasks with the current state-of-the-art.

- Precision: Achieve more precise results with modern measurement hardware and actuators.

- Safety: Integration of the newest safety technology adapts your test bench to current regulations.

- Compatibility: The requirements of your modern IT systems are met.

- Cost savings: Modernization is more cost-effective than building a completely new solution.

- Maintenance advantages: Uniform hardware and software saves maintenance and training costs.

- Sustainability: Functional systems and maintained and optimized.

The success factors of our modernization solutions:

Careful updating

As an independent system integrator, measX is not bound to complete systems of specific manufacturers. An individual modernization solution is developed for every testing situation, including a precise analysis of whether existing components can be expanded or replaced.

Step by step modernization to meet current demands:

- Detailed analysis of the current situation and future needs

- Consultation

- Individual modernization concept

- Implementation planning (soft migration, if possible)

- Realization (hardware and software)

- Integration/commissioning

- Training and documentation

- Maintenance, service and support

- Supplemental services

Soft migration

If the test bench to be modernized is stationary, we do everything we can to keep downtimes as short as possible.

As far as possible, we carry out a soft migration. A fall-back strategy exists at every point in time so that the original status can be restored, if necessary.

Custom test bench modernization for long-term, efficient operation

In the face of ever shorter production and product life cycles as well as continuously changing safety requirements and environmental standards, measurement and testing systems must be constantly adapted. For example, new product generations require different, often significantly more complex test procedures.

Depending on the modernization objective, however, test systems do not need to be completely rebuilt. This is because the lifespans of the individual components differ widely: It is not rare for the computer technology and data acquisition to require urgent replacement while the automation components, hydraulics and electrical systems require no modernization.

measX is a specialist in individual modernization concepts: First, the requirements on the modernization are carefully analyzed. On this basis, we develop a recommendation that perfectly addresses all the requirements and takes future developments into account as well as possible.

With intelligent modernization, you can optimize the quality of your measurement and testing processes.

Your benefits:

- Competitiveness: Carry out testing tasks with the current state-of-the-art.

- Precision: Achieve more precise results with modern measurement hardware and actuators.

- Safety: Integration of the newest safety technology adapts your test bench to current regulations.

- Compatibility: The requirements of your modern IT systems are met.

- Cost savings: Modernization is more cost-effective than building a completely new solution.

- Maintenance advantages: Uniform hardware and software saves maintenance and training costs.

- Sustainability: Functional systems and maintained and optimized.

The success factors of our modernization solutions:

Careful updating

As an independent system integrator, measX is not bound to complete systems of specific manufacturers. An individual modernization solution is developed for every testing situation, including a precise analysis of whether existing components can be expanded or replaced.

Step by step modernization to meet current demands:

- Detailed analysis of the current situation and future needs

- Consultation

- Individual modernization concept

- Implementation planning (soft migration, if possible)

- Realization (hardware and software)

- Integration/commissioning

- Training and documentation

- Maintenance, service and support

- Supplemental services

Soft migration

If the test bench to be modernized is stationary, we do everything we can to keep downtimes as short as possible.

As far as possible, we carry out a soft migration. A fall-back strategy exists at every point in time so that the original status can be restored, if necessary.

Custom test bench modernization for long-term, efficient operation

In the face of ever shorter production and product life cycles as well as continuously changing safety requirements and environmental standards, measurement and testing systems must be constantly adapted. For example, new product generations require different, often significantly more complex test procedures.

Depending on the modernization objective, however, test systems do not need to be completely rebuilt. This is because the lifespans of the individual components differ widely: It is not rare for the computer technology and data acquisition to require urgent replacement while the automation components, hydraulics and electrical systems require no modernization.

measX is a specialist in individual modernization concepts: First, the requirements on the modernization are carefully analyzed. On this basis, we develop a recommendation that perfectly addresses all the requirements and takes future developments into account as well as possible.

With intelligent modernization, you can optimize the quality of your measurement and testing processes.

Your benefits:

- Competitiveness: Carry out testing tasks with the current state-of-the-art.

- Precision: Achieve more precise results with modern measurement hardware and actuators.

- Safety: Integration of the newest safety technology adapts your test bench to current regulations.

- Compatibility: The requirements of your modern IT systems are met.

- Cost savings: Modernization is more cost-effective than building a completely new solution.

- Maintenance advantages: Uniform hardware and software saves maintenance and training costs.

- Sustainability: Functional systems and maintained and optimized.

The success factors of our modernization solutions:

Careful updating

As an independent system integrator, measX is not bound to complete systems of specific manufacturers. An individual modernization solution is developed for every testing situation, including a precise analysis of whether existing components can be expanded or replaced.

Step by step modernization to meet current demands:

- Detailed analysis of the current situation and future needs

- Consultation

- Individual modernization concept

- Implementation planning (soft migration, if possible)

- Realization (hardware and software)

- Integration/commissioning

- Training and documentation

- Maintenance, service and support

- Supplemental services

Soft migration

If the test bench to be modernized is stationary, we do everything we can to keep downtimes as short as possible.

As far as possible, we carry out a soft migration. A fall-back strategy exists at every point in time so that the original status can be restored, if necessary.

Custom test bench modernization for long-term, efficient operation

In the face of ever shorter production and product life cycles as well as continuously changing safety requirements and environmental standards, measurement and testing systems must be constantly adapted. For example, new product generations require different, often significantly more complex test procedures.

Depending on the modernization objective, however, test systems do not need to be completely rebuilt. This is because the lifespans of the individual components differ widely: It is not rare for the computer technology and data acquisition to require urgent replacement while the automation components, hydraulics and electrical systems require no modernization.

measX is a specialist in individual modernization concepts: First, the requirements on the modernization are carefully analyzed. On this basis, we develop a recommendation that perfectly addresses all the requirements and takes future developments into account as well as possible.

With intelligent modernization, you can optimize the quality of your measurement and testing processes.

Your benefits:

- Competitiveness: Carry out testing tasks with the current state-of-the-art.

- Precision: Achieve more precise results with modern measurement hardware and actuators.

- Safety: Integration of the newest safety technology adapts your test bench to current regulations.

- Compatibility: The requirements of your modern IT systems are met.

- Cost savings: Modernization is more cost-effective than building a completely new solution.

- Maintenance advantages: Uniform hardware and software saves maintenance and training costs.

- Sustainability: Functional systems and maintained and optimized.

The success factors of our modernization solutions:

Careful updating

As an independent system integrator, measX is not bound to complete systems of specific manufacturers. An individual modernization solution is developed for every testing situation, including a precise analysis of whether existing components can be expanded or replaced.

Step by step modernization to meet current demands:

- Detailed analysis of the current situation and future needs

- Consultation

- Individual modernization concept

- Implementation planning (soft migration, if possible)

- Realization (hardware and software)

- Integration/commissioning

- Training and documentation

- Maintenance, service and support

- Supplemental services

Soft migration

If the test bench to be modernized is stationary, we do everything we can to keep downtimes as short as possible.

As far as possible, we carry out a soft migration. A fall-back strategy exists at every point in time so that the original status can be restored, if necessary.

Custom test bench modernization for long-term, efficient operation

In the face of ever shorter production and product life cycles as well as continuously changing safety requirements and environmental standards, measurement and testing systems must be constantly adapted. For example, new product generations require different, often significantly more complex test procedures.

Depending on the modernization objective, however, test systems do not need to be completely rebuilt. This is because the lifespans of the individual components differ widely: It is not rare for the computer technology and data acquisition to require urgent replacement while the automation components, hydraulics and electrical systems require no modernization.

measX is a specialist in individual modernization concepts: First, the requirements on the modernization are carefully analyzed. On this basis, we develop a recommendation that perfectly addresses all the requirements and takes future developments into account as well as possible.

With intelligent modernization, you can optimize the quality of your measurement and testing processes.

Your benefits:

- Competitiveness: Carry out testing tasks with the current state-of-the-art.

- Precision: Achieve more precise results with modern measurement hardware and actuators.

- Safety: Integration of the newest safety technology adapts your test bench to current regulations.

- Compatibility: The requirements of your modern IT systems are met.

- Cost savings: Modernization is more cost-effective than building a completely new solution.

- Maintenance advantages: Uniform hardware and software saves maintenance and training costs.

- Sustainability: Functional systems and maintained and optimized.

The success factors of our modernization solutions:

Careful updating

As an independent system integrator, measX is not bound to complete systems of specific manufacturers. An individual modernization solution is developed for every testing situation, including a precise analysis of whether existing components can be expanded or replaced.

Step by step modernization to meet current demands:

- Detailed analysis of the current situation and future needs

- Consultation

- Individual modernization concept

- Implementation planning (soft migration, if possible)

- Realization (hardware and software)

- Integration/commissioning

- Training and documentation

- Maintenance, service and support

- Supplemental services

Soft migration

If the test bench to be modernized is stationary, we do everything we can to keep downtimes as short as possible.

As far as possible, we carry out a soft migration. A fall-back strategy exists at every point in time so that the original status can be restored, if necessary.

Custom test bench modernization for long-term, efficient operation

In the face of ever shorter production and product life cycles as well as continuously changing safety requirements and environmental standards, measurement and testing systems must be constantly adapted. For example, new product generations require different, often significantly more complex test procedures.

Depending on the modernization objective, however, test systems do not need to be completely rebuilt. This is because the lifespans of the individual components differ widely: It is not rare for the computer technology and data acquisition to require urgent replacement while the automation components, hydraulics and electrical systems require no modernization.

measX is a specialist in individual modernization concepts: First, the requirements on the modernization are carefully analyzed. On this basis, we develop a recommendation that perfectly addresses all the requirements and takes future developments into account as well as possible.

With intelligent modernization, you can optimize the quality of your measurement and testing processes.

Your benefits:

- Competitiveness: Carry out testing tasks with the current state-of-the-art.

- Precision: Achieve more precise results with modern measurement hardware and actuators.

- Safety: Integration of the newest safety technology adapts your test bench to current regulations.

- Compatibility: The requirements of your modern IT systems are met.

- Cost savings: Modernization is more cost-effective than building a completely new solution.

- Maintenance advantages: Uniform hardware and software saves maintenance and training costs.

- Sustainability: Functional systems and maintained and optimized.

The success factors of our modernization solutions:

Careful updating

As an independent system integrator, measX is not bound to complete systems of specific manufacturers. An individual modernization solution is developed for every testing situation, including a precise analysis of whether existing components can be expanded or replaced.

Step by step modernization to meet current demands:

- Detailed analysis of the current situation and future needs

- Consultation

- Individual modernization concept

- Implementation planning (soft migration, if possible)

- Realization (hardware and software)

- Integration/commissioning

- Training and documentation

- Maintenance, service and support

- Supplemental services

Soft migration

If the test bench to be modernized is stationary, we do everything we can to keep downtimes as short as possible.

As far as possible, we carry out a soft migration. A fall-back strategy exists at every point in time so that the original status can be restored, if necessary.

Custom test bench modernization for long-term, efficient operation

In the face of ever shorter production and product life cycles as well as continuously changing safety requirements and environmental standards, measurement and testing systems must be constantly adapted. For example, new product generations require different, often significantly more complex test procedures.

Depending on the modernization objective, however, test systems do not need to be completely rebuilt. This is because the lifespans of the individual components differ widely: It is not rare for the computer technology and data acquisition to require urgent replacement while the automation components, hydraulics and electrical systems require no modernization.

measX is a specialist in individual modernization concepts: First, the requirements on the modernization are carefully analyzed. On this basis, we develop a recommendation that perfectly addresses all the requirements and takes future developments into account as well as possible.

With intelligent modernization, you can optimize the quality of your measurement and testing processes.

Your benefits:

- Competitiveness: Carry out testing tasks with the current state-of-the-art.

- Precision: Achieve more precise results with modern measurement hardware and actuators.

- Safety: Integration of the newest safety technology adapts your test bench to current regulations.

- Compatibility: The requirements of your modern IT systems are met.

- Cost savings: Modernization is more cost-effective than building a completely new solution.

- Maintenance advantages: Uniform hardware and software saves maintenance and training costs.

- Sustainability: Functional systems and maintained and optimized.

The success factors of our modernization solutions:

Careful updating

As an independent system integrator, measX is not bound to complete systems of specific manufacturers. An individual modernization solution is developed for every testing situation, including a precise analysis of whether existing components can be expanded or replaced.

Step by step modernization to meet current demands:

- Detailed analysis of the current situation and future needs

- Consultation

- Individual modernization concept

- Implementation planning (soft migration, if possible)

- Realization (hardware and software)

- Integration/commissioning

- Training and documentation

- Maintenance, service and support

- Supplemental services

Soft migration

If the test bench to be modernized is stationary, we do everything we can to keep downtimes as short as possible.

As far as possible, we carry out a soft migration. A fall-back strategy exists at every point in time so that the original status can be restored, if necessary.

Custom test bench modernization for long-term, efficient operation

In the face of ever shorter production and product life cycles as well as continuously changing safety requirements and environmental standards, measurement and testing systems must be constantly adapted. For example, new product generations require different, often significantly more complex test procedures.

Depending on the modernization objective, however, test systems do not need to be completely rebuilt. This is because the lifespans of the individual components differ widely: It is not rare for the computer technology and data acquisition to require urgent replacement while the automation components, hydraulics and electrical systems require no modernization.

measX is a specialist in individual modernization concepts: First, the requirements on the modernization are carefully analyzed. On this basis, we develop a recommendation that perfectly addresses all the requirements and takes future developments into account as well as possible.

With intelligent modernization, you can optimize the quality of your measurement and testing processes.

Your benefits:

- Competitiveness: Carry out testing tasks with the current state-of-the-art.

- Precision: Achieve more precise results with modern measurement hardware and actuators.

- Safety: Integration of the newest safety technology adapts your test bench to current regulations.

- Compatibility: The requirements of your modern IT systems are met.

- Cost savings: Modernization is more cost-effective than building a completely new solution.

- Maintenance advantages: Uniform hardware and software saves maintenance and training costs.

- Sustainability: Functional systems and maintained and optimized.

The success factors of our modernization solutions:

Careful updating

As an independent system integrator, measX is not bound to complete systems of specific manufacturers. An individual modernization solution is developed for every testing situation, including a precise analysis of whether existing components can be expanded or replaced.

Step by step modernization to meet current demands:

- Detailed analysis of the current situation and future needs

- Consultation

- Individual modernization concept

- Implementation planning (soft migration, if possible)

- Realization (hardware and software)

- Integration/commissioning

- Training and documentation

- Maintenance, service and support

- Supplemental services

Soft migration

If the test bench to be modernized is stationary, we do everything we can to keep downtimes as short as possible.

As far as possible, we carry out a soft migration. A fall-back strategy exists at every point in time so that the original status can be restored, if necessary.

Custom test bench modernization for long-term, efficient operation

In the face of ever shorter production and product life cycles as well as continuously changing safety requirements and environmental standards, measurement and testing systems must be constantly adapted. For example, new product generations require different, often significantly more complex test procedures.

Depending on the modernization objective, however, test systems do not need to be completely rebuilt. This is because the lifespans of the individual components differ widely: It is not rare for the computer technology and data acquisition to require urgent replacement while the automation components, hydraulics and electrical systems require no modernization.

measX is a specialist in individual modernization concepts: First, the requirements on the modernization are carefully analyzed. On this basis, we develop a recommendation that perfectly addresses all the requirements and takes future developments into account as well as possible.

With intelligent modernization, you can optimize the quality of your measurement and testing processes.

Your benefits:

- Competitiveness: Carry out testing tasks with the current state-of-the-art.

- Precision: Achieve more precise results with modern measurement hardware and actuators.

- Safety: Integration of the newest safety technology adapts your test bench to current regulations.

- Compatibility: The requirements of your modern IT systems are met.

- Cost savings: Modernization is more cost-effective than building a completely new solution.

- Maintenance advantages: Uniform hardware and software saves maintenance and training costs.

- Sustainability: Functional systems and maintained and optimized.

The success factors of our modernization solutions:

Careful updating

As an independent system integrator, measX is not bound to complete systems of specific manufacturers. An individual modernization solution is developed for every testing situation, including a precise analysis of whether existing components can be expanded or replaced.

Step by step modernization to meet current demands:

- Detailed analysis of the current situation and future needs

- Consultation

- Individual modernization concept

- Implementation planning (soft migration, if possible)

- Realization (hardware and software)

- Integration/commissioning

- Training and documentation

- Maintenance, service and support

- Supplemental services

Soft migration

If the test bench to be modernized is stationary, we do everything we can to keep downtimes as short as possible.

As far as possible, we carry out a soft migration. A fall-back strategy exists at every point in time so that the original status can be restored, if necessary.

Custom test bench modernization for long-term, efficient operation

In the face of ever shorter production and product life cycles as well as continuously changing safety requirements and environmental standards, measurement and testing systems must be constantly adapted. For example, new product generations require different, often significantly more complex test procedures.

Depending on the modernization objective, however, test systems do not need to be completely rebuilt. This is because the lifespans of the individual components differ widely: It is not rare for the computer technology and data acquisition to require urgent replacement while the automation components, hydraulics and electrical systems require no modernization.

measX is a specialist in individual modernization concepts: First, the requirements on the modernization are carefully analyzed. On this basis, we develop a recommendation that perfectly addresses all the requirements and takes future developments into account as well as possible.

With intelligent modernization, you can optimize the quality of your measurement and testing processes.

Your benefits:

- Competitiveness: Carry out testing tasks with the current state-of-the-art.

- Precision: Achieve more precise results with modern measurement hardware and actuators.

- Safety: Integration of the newest safety technology adapts your test bench to current regulations.

- Compatibility: The requirements of your modern IT systems are met.

- Cost savings: Modernization is more cost-effective than building a completely new solution.

- Maintenance advantages: Uniform hardware and software saves maintenance and training costs.

- Sustainability: Functional systems and maintained and optimized.

The success factors of our modernization solutions:

Careful updating

As an independent system integrator, measX is not bound to complete systems of specific manufacturers. An individual modernization solution is developed for every testing situation, including a precise analysis of whether existing components can be expanded or replaced.

Step by step modernization to meet current demands:

- Detailed analysis of the current situation and future needs

- Consultation

- Individual modernization concept

- Implementation planning (soft migration, if possible)

- Realization (hardware and software)

- Integration/commissioning

- Training and documentation

- Maintenance, service and support

- Supplemental services

Soft migration

If the test bench to be modernized is stationary, we do everything we can to keep downtimes as short as possible.

As far as possible, we carry out a soft migration. A fall-back strategy exists at every point in time so that the original status can be restored, if necessary.

Custom test bench modernization for long-term, efficient operation

In the face of ever shorter production and product life cycles as well as continuously changing safety requirements and environmental standards, measurement and testing systems must be constantly adapted. For example, new product generations require different, often significantly more complex test procedures.

Depending on the modernization objective, however, test systems do not need to be completely rebuilt. This is because the lifespans of the individual components differ widely: It is not rare for the computer technology and data acquisition to require urgent replacement while the automation components, hydraulics and electrical systems require no modernization.

measX is a specialist in individual modernization concepts: First, the requirements on the modernization are carefully analyzed. On this basis, we develop a recommendation that perfectly addresses all the requirements and takes future developments into account as well as possible.

With intelligent modernization, you can optimize the quality of your measurement and testing processes.

Your benefits:

- Competitiveness: Carry out testing tasks with the current state-of-the-art.

- Precision: Achieve more precise results with modern measurement hardware and actuators.

- Safety: Integration of the newest safety technology adapts your test bench to current regulations.

- Compatibility: The requirements of your modern IT systems are met.

- Cost savings: Modernization is more cost-effective than building a completely new solution.

- Maintenance advantages: Uniform hardware and software saves maintenance and training costs.

- Sustainability: Functional systems and maintained and optimized.

The success factors of our modernization solutions:

Examples of the modernized test systems:

Highly dynamic test bench for testing car wheels ...>

Distributed data acquisition in a production plant for the manufacturing of special cables ...>

Test bench for hall sensors in the laboratory and production ...>

Broad user experience

Modernization is part of our core business, and we provide this service to diverse industries and in the face of widely varying requirements.

With measX, you can choose from a broad spectrum of state-of-the-art measurement hardware and software. The main aspects to be modernized are generally better signal processing, higher-performance computer systems or the digitalization of sensors in order to achieve the goal of less susceptibility to errors as well as faster data acquisition and data processing.

No fear of hard problems

One major challenge of modernizing test benches is that the systems to be updated have frequently grown over the course of decades, and not every change to the electrical systems, actuators or hardware was sufficiently well documented.

Thanks to its immense application experience, measX is perfectly equipped to truly “understand” an old system and develop a modernization solution that meets the requirements while also being optimized for cost.

Examples of the modernized test systems:

Highly dynamic test bench for testing car wheels ...>

Distributed data acquisition in a production plant for the manufacturing of special cables ...>

Test bench for hall sensors in the laboratory and production ...>

Broad user experience

Modernization is part of our core business, and we provide this service to diverse industries and in the face of widely varying requirements.

With measX, you can choose from a broad spectrum of state-of-the-art measurement hardware and software. The main aspects to be modernized are generally better signal processing, higher-performance computer systems or the digitalization of sensors in order to achieve the goal of less susceptibility to errors as well as faster data acquisition and data processing.

No fear of hard problems

One major challenge of modernizing test benches is that the systems to be updated have frequently grown over the course of decades, and not every change to the electrical systems, actuators or hardware was sufficiently well documented.

Thanks to its immense application experience, measX is perfectly equipped to truly “understand” an old system and develop a modernization solution that meets the requirements while also being optimized for cost.

Examples of the modernized test systems:

Highly dynamic test bench for testing car wheels ...>

Distributed data acquisition in a production plant for the manufacturing of special cables ...>

Test bench for hall sensors in the laboratory and production ...>

Broad user experience

Modernization is part of our core business, and we provide this service to diverse industries and in the face of widely varying requirements.

With measX, you can choose from a broad spectrum of state-of-the-art measurement hardware and software. The main aspects to be modernized are generally better signal processing, higher-performance computer systems or the digitalization of sensors in order to achieve the goal of less susceptibility to errors as well as faster data acquisition and data processing.

No fear of hard problems

One major challenge of modernizing test benches is that the systems to be updated have frequently grown over the course of decades, and not every change to the electrical systems, actuators or hardware was sufficiently well documented.

Thanks to its immense application experience, measX is perfectly equipped to truly “understand” an old system and develop a modernization solution that meets the requirements while also being optimized for cost.

Examples of the modernized test systems:

Highly dynamic test bench for testing car wheels ...>

Distributed data acquisition in a production plant for the manufacturing of special cables ...>

Test bench for hall sensors in the laboratory and production ...>

Broad user experience

Modernization is part of our core business, and we provide this service to diverse industries and in the face of widely varying requirements.

With measX, you can choose from a broad spectrum of state-of-the-art measurement hardware and software. The main aspects to be modernized are generally better signal processing, higher-performance computer systems or the digitalization of sensors in order to achieve the goal of less susceptibility to errors as well as faster data acquisition and data processing.

No fear of hard problems

One major challenge of modernizing test benches is that the systems to be updated have frequently grown over the course of decades, and not every change to the electrical systems, actuators or hardware was sufficiently well documented.

Thanks to its immense application experience, measX is perfectly equipped to truly “understand” an old system and develop a modernization solution that meets the requirements while also being optimized for cost.

Examples of the modernized test systems:

Highly dynamic test bench for testing car wheels ...>

Distributed data acquisition in a production plant for the manufacturing of special cables ...>

Test bench for hall sensors in the laboratory and production ...>

Broad user experience

Modernization is part of our core business, and we provide this service to diverse industries and in the face of widely varying requirements.

With measX, you can choose from a broad spectrum of state-of-the-art measurement hardware and software. The main aspects to be modernized are generally better signal processing, higher-performance computer systems or the digitalization of sensors in order to achieve the goal of less susceptibility to errors as well as faster data acquisition and data processing.

No fear of hard problems

One major challenge of modernizing test benches is that the systems to be updated have frequently grown over the course of decades, and not every change to the electrical systems, actuators or hardware was sufficiently well documented.

Thanks to its immense application experience, measX is perfectly equipped to truly “understand” an old system and develop a modernization solution that meets the requirements while also being optimized for cost.

Examples of the modernized test systems:

Highly dynamic test bench for testing car wheels ...>

Distributed data acquisition in a production plant for the manufacturing of special cables ...>

Test bench for hall sensors in the laboratory and production ...>

Broad user experience

Modernization is part of our core business, and we provide this service to diverse industries and in the face of widely varying requirements.

With measX, you can choose from a broad spectrum of state-of-the-art measurement hardware and software. The main aspects to be modernized are generally better signal processing, higher-performance computer systems or the digitalization of sensors in order to achieve the goal of less susceptibility to errors as well as faster data acquisition and data processing.

No fear of hard problems

One major challenge of modernizing test benches is that the systems to be updated have frequently grown over the course of decades, and not every change to the electrical systems, actuators or hardware was sufficiently well documented.

Thanks to its immense application experience, measX is perfectly equipped to truly “understand” an old system and develop a modernization solution that meets the requirements while also being optimized for cost.

Examples of the modernized test systems:

Highly dynamic test bench for testing car wheels ...>

Distributed data acquisition in a production plant for the manufacturing of special cables ...>

Test bench for hall sensors in the laboratory and production ...>

Broad user experience

Modernization is part of our core business, and we provide this service to diverse industries and in the face of widely varying requirements.

With measX, you can choose from a broad spectrum of state-of-the-art measurement hardware and software. The main aspects to be modernized are generally better signal processing, higher-performance computer systems or the digitalization of sensors in order to achieve the goal of less susceptibility to errors as well as faster data acquisition and data processing.

No fear of hard problems

One major challenge of modernizing test benches is that the systems to be updated have frequently grown over the course of decades, and not every change to the electrical systems, actuators or hardware was sufficiently well documented.

Thanks to its immense application experience, measX is perfectly equipped to truly “understand” an old system and develop a modernization solution that meets the requirements while also being optimized for cost.

Examples of the modernized test systems:

Highly dynamic test bench for testing car wheels ...>

Distributed data acquisition in a production plant for the manufacturing of special cables ...>

Test bench for hall sensors in the laboratory and production ...>

Broad user experience

Modernization is part of our core business, and we provide this service to diverse industries and in the face of widely varying requirements.

With measX, you can choose from a broad spectrum of state-of-the-art measurement hardware and software. The main aspects to be modernized are generally better signal processing, higher-performance computer systems or the digitalization of sensors in order to achieve the goal of less susceptibility to errors as well as faster data acquisition and data processing.

No fear of hard problems

One major challenge of modernizing test benches is that the systems to be updated have frequently grown over the course of decades, and not every change to the electrical systems, actuators or hardware was sufficiently well documented.

Thanks to its immense application experience, measX is perfectly equipped to truly “understand” an old system and develop a modernization solution that meets the requirements while also being optimized for cost.

Examples of the modernized test systems:

Highly dynamic test bench for testing car wheels ...>

Distributed data acquisition in a production plant for the manufacturing of special cables ...>

Test bench for hall sensors in the laboratory and production ...>

Broad user experience

Modernization is part of our core business, and we provide this service to diverse industries and in the face of widely varying requirements.

With measX, you can choose from a broad spectrum of state-of-the-art measurement hardware and software. The main aspects to be modernized are generally better signal processing, higher-performance computer systems or the digitalization of sensors in order to achieve the goal of less susceptibility to errors as well as faster data acquisition and data processing.

No fear of hard problems

One major challenge of modernizing test benches is that the systems to be updated have frequently grown over the course of decades, and not every change to the electrical systems, actuators or hardware was sufficiently well documented.

Thanks to its immense application experience, measX is perfectly equipped to truly “understand” an old system and develop a modernization solution that meets the requirements while also being optimized for cost.

Examples of the modernized test systems:

Highly dynamic test bench for testing car wheels ...>

Distributed data acquisition in a production plant for the manufacturing of special cables ...>

Test bench for hall sensors in the laboratory and production ...>

Broad user experience

Modernization is part of our core business, and we provide this service to diverse industries and in the face of widely varying requirements.

With measX, you can choose from a broad spectrum of state-of-the-art measurement hardware and software. The main aspects to be modernized are generally better signal processing, higher-performance computer systems or the digitalization of sensors in order to achieve the goal of less susceptibility to errors as well as faster data acquisition and data processing.

No fear of hard problems

One major challenge of modernizing test benches is that the systems to be updated have frequently grown over the course of decades, and not every change to the electrical systems, actuators or hardware was sufficiently well documented.

Thanks to its immense application experience, measX is perfectly equipped to truly “understand” an old system and develop a modernization solution that meets the requirements while also being optimized for cost.

Examples of the modernized test systems:

Highly dynamic test bench for testing car wheels ...>

Distributed data acquisition in a production plant for the manufacturing of special cables ...>

Test bench for hall sensors in the laboratory and production ...>