Automated status monitoring for large rolling-contact bearing

Customer: RWE Power AG

Area: Energy industry / production

Requirements: Monitoring of axial self-aligning roller bearing, diameter 1,500 mm, weight approx. 2,700 kg

Implementation: Hardware: NI single-board RIO / software: LabVIEW

Far-sighted maintenance

The initial situation

RWE Power AG is one of the leading energy production and generation companies in Germany and has more than a dozen power plants in the country. Nine of these are coal power plants in which the combustion air for the boilers is preheated via rotary heat exchangers. Their supporting bearings turn very slowly and are subjected to extremely high loads. Even the smallest damage to the bearing can result in devastating damages if it remains undetected for too long. A spontaneous bearing failure can even put the power plant out of operation for a number of days, resulting in immense costs.

The task

Ensuring the smooth operation of the air pre-heaters and preventing unplanned interruptions of production is a major challenge. Waiting for damage to occur and carrying out purely corrective maintenance represents an unsatisfactory solution due to the incalculable risk. Purely preventive maintenance of the large rolling-contact bearings is also less than ideal. Simply shortening the inspection intervals would not provide any absolute safety and would also be uneconomical. The ideal solution is instead predictive maintenance that is based on the actual condition of the supporting bearings. Implementing this maintenance strategy at RWE Power required a reliable, constantly operating test system.

Our solution

The development of an automated monitoring system capable of responding to even the smallest damage was a challenging task. This is because the applicable method of frequency analysis could not be implemented without additional measures due to environmental conditions that included sometimes stochastic vibration components. The very brief, periodic shock pulses that occurred upon rolling over early stage bearing damage were very weak, while there was at the same time a great many interfering mechanical signals and electronic noise that had far more energy. It was possible, however, to significantly improve the unfavorable signal-to-noise ratio by means of mathematical methods and to differentiate stochastic from periodic signal components.

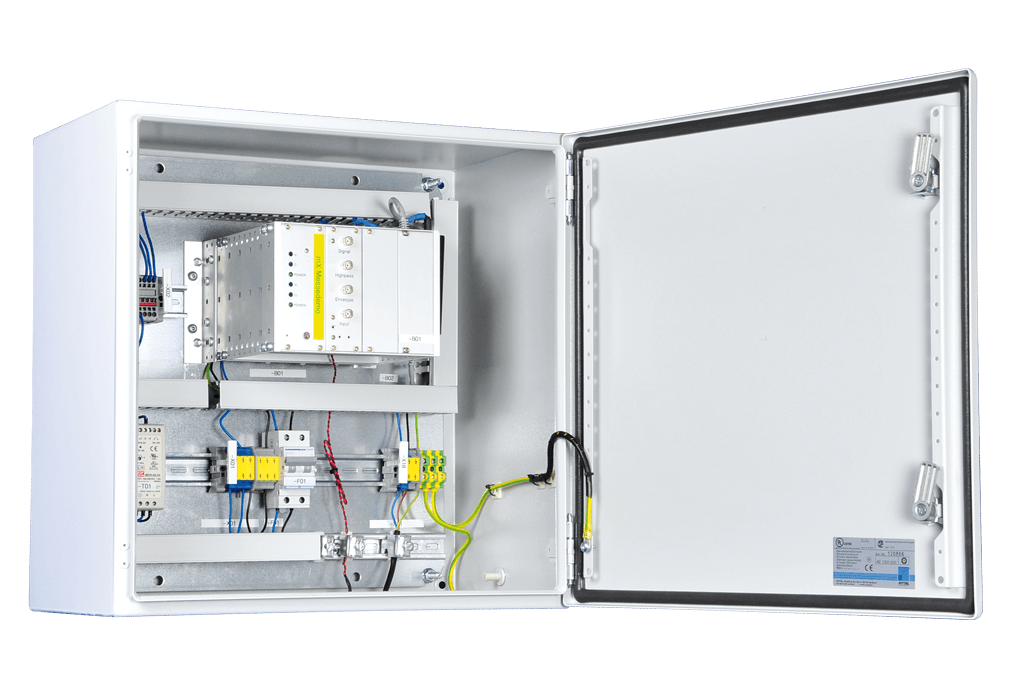

Intelligent hardware and plenty of mathematics

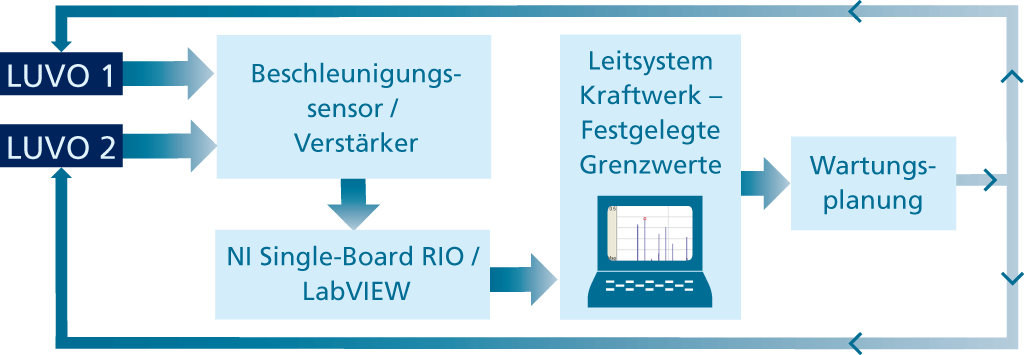

The solution was based on a combination of especially low-noise electronic components and special mathematical algorithms. First, the signals recorded on the rolling-contact bearings with sensitive acceleration sensors are filtered through a high-precision, low-noise amplifier and demodulated. The subsequent digital processing takes place in LabVIEW in an intelligent data acquisition system (NI single-board RIO). From here, the extracted values are automatically sent via Ethernet to the diagnostic station of the power plant, where the limit values are monitored.

Efficient development process

The analysis procedure was developed with DASYLab, which has a great many standard signal analysis methods and procedures, meaning that various approaches could be tried out without the need for time-consuming programming. A prototype based on a PC running DASYLab was operated for half a year at the Niederaußem plant, a large power plant of RWE Power AG. The final system was eventually implemented in LabVIEW on an NI single-board RIO.

In practical use

The automated test system will in future continuously monitor the status of the heavily stressed, slowly turning rolling-contact bearings of the air pre-heaters at various power plants of RWE Power and establish the foundation for efficient maintenance processes. The captured signals are analyzed for several minutes at defined intervals, and the values are automatically forwarded to the diagnostic station of the power plant via Ethernet. Even the smallest signs of wear on the large bearings can be reliably detected. The limit values are defined such as to allow sufficient time to carefully plan and efficiently carry out the repairs. The robust test system operates autonomously and requires no outside intervention. If necessary, however, it can also be easily configured via the control system.

Reliable status monitoring:

- Registration of even the smallest damage

- Online reporting to the control station

- No interruption of operation during the measurement

- Robust, low-maintenance hardware without a PC

The complete case study as a PDF