Analysis system for mobile data loggers with web interface

Customer: Daimler AG

Area: Automotive / R&D

Requirements: Endurance test of commercial vehicle fleet in 24/7 operation, approx. 100 GB data/day

Implementation: measX software X-Frame, ASAM-ODS database

Always up-to-date

The initial situation

For testing and optimizing their utility vehicles, Daimler AG operates a fleet of vehicles equipped with measurement systems. The trucks travel routes of various profiles around the clock in three-shift operation. Several hundred signals related to the vehicle’s operation are recorded over an entire shift: temperatures, pressures, rotation speeds, brake pedal operations, accelerations and shifting operations as well as a large number of controller parameters. Several gigabyte of raw data is collected per vehicle and shift and automatically transmitted to a central server.

The task

The customer desired a convenient system capable of automatically and quickly analysing the large quantity of test data both per-shift and over periods longer than a single shift. In the further course of the project, the wish arose to integrate additional data stocks and to make all information of the road endurance test available via a web application.

Our solution

Today's solution has grown over a period of several years. It was realized with the measX software tool X-Frame, which is based on the standard software DIAdem from National Instruments. Finally the evaluation platform MBTaps (Mercedes-Benz Truck Analysis Platform System) was developed. Central components of the system are a powerful database, an automated evaluation system that can be flexibly adapted to changing requirements, and a clear web portal.

Structured, efficient data import

The incoming measurement data is automatically sorted and imported via an importer. At this time, redundant channels are eliminated, the sampling rates of differently recorded signals are adapted to each other and the data for each eight-hour shift is collected into exactly one file. Each new shift file is registered in the overarching ASAM-ODS database (measurement management). Thanks to 64 bits and parallel processes, all incoming data is processed in a short time. A monitor dialog informs about the current status of the data import. In case of anomalies, the import process for this vehicle stops until the problem is identified. All incoming raw data is checked in the importer for plausibility, and faulty data is tagged and stored separately.

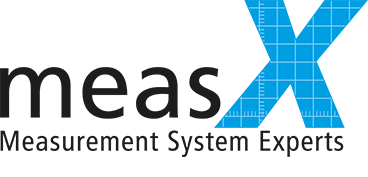

Fully automatic precalculations

New entries in the ASAM-ODS database are automatically detected and processed. In just a few minutes, hundreds of scalar characteristic values, classification channels and formulas for the measured signals are calculated from the data of a shift and stored in the database. This significantly reduces the volume of data and the processing time during all subsequent calculation steps. In addition, numerous meta information is transferred to the database. It forms the basis for all subsequent analyses. Mass data only has to be accessed in exceptional cases.

Individual analyses

Analyses spanning multiple shifts can beperformed with MBTaps for all areas of interest. The X-Frame analysis system offers configurable DIAdem analyses for this purpose that can be easily adapted to the specific requirements without any programming work. All calculations and analyses can be freely configured by the users for each individual vehicle. In addition, the users can modularly create individual formulas and assemble them into entire calculations.

High availability

The fully automatic import processes, preliminary calculations and evaluations are carried out independently on central hosted servers. To ensure the stability of the unattended processes, control mechanisms such as memory monitoring, vital sign query and automatic restart have been integrated.

Overview in the web portal

Through the integration of web-based functions a significant added value was created. All information and reports for the test drives can be found in the company intranet via a clearly arranged web dashboard independent of time, location, and platform and can be used for analyses.

Details about the endurance run

The actual status of each individual test vehicle is recognizable. Specific values from precalculations and statistical evaluations can be tabular or graphically displayed. For further processing all data can be stored in files.

Map view with characteristic values

The shift data are recorded with GPS data and supplemented with metadata about street conditions. In the web browser, the routes of one or more vehicles can be displayed and compared. You can also use several filters for specific periods of time or shifts. The track view also informs about the status and the change of signals. Especially frequent events are identified as so-called hot spots.

Link to the software version

The software versions of the ECUs are continuously determined by an automated process via CAN bus queries and compared with the database. They are automatically assigned to the measurements so that a software version specific analysis is possible via the web portal. The information on the software version can also be exported as meta information with the characteristic values and used for further evaluations.

In practical use

MBTaps is successfully used in the utility vehicle sector of Mercedes-Benz to record and evaluate test data continuously. Automated preliminary calculations relieve the engineer and provide valuable statistics and characteristic values, which considerably facilitate the control and monitoring of the road endurance test. Shift and weekly evaluations are stored centrally as a PDF report and are available to the specialist departments via the web portal. If required also annual evaluations or evaluations over a complete continuous operation cycle, as well as special analyses are provided internally. As a powerful information and analysis system, MBTaps is an indispensable tool for commercial vehicle development. The open system is continuously adapted to new requirements.

Introductory image: © Daimler AG

Download the complete case study as a PDF