Evaluation system for shock absorber test bench

Customer: Audi AG

Area: Automotive / R&D

Requirements: Expanded data analysis on a shock absorber test bench with temperature chamber

Implementation: measX software X-Frame in connection with an Athos ASAM server

Standards for individualists

The initial situation

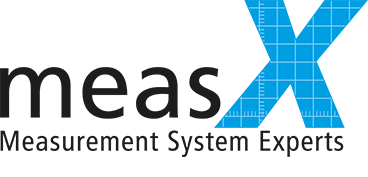

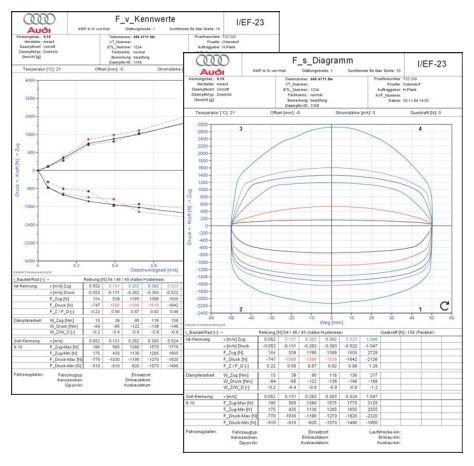

Characteristic values of shock absorbers are measured on the shock absorber test bench of Audi AG to serve as a basis for providing series and development samples for practical suspension/shock absorber tuning. The test bench is equipped with a temperature chamber and allows investigations in a temperature range from -40 to +80 degrees Celsius. Other key features are test amplitudes from 0 to 125 mm, test speeds from 0.2 mm/s to 3 m/s and test sequences from 0 to 60 Hz. The maximum test force is 30 kN. The test bench is operated via PC software that also carries out a preliminary evaluation. The result is simple diagrams with characteristic curves for the shock absorber behavior at various test speeds. However, no customer-specific adaptation of this preliminary evaluation is possible.

Characteristic values of shock absorbers are measured on the shock absorber test bench of Audi AG to serve as a basis for providing series and development samples for practical suspension/shock absorber tuning. The test bench is equipped with a temperature chamber and allows investigations in a temperature range from -40 to +80 degrees Celsius. Other key features are test amplitudes from 0 to 125 mm, test speeds from 0.2 mm/s to 3 m/s and test sequences from 0 to 60 Hz. The maximum test force is 30 kN. The test bench is operated via PC software that also carries out a preliminary evaluation. The result is simple diagrams with characteristic curves for the shock absorber behavior at various test speeds. However, no customer-specific adaptation of this preliminary evaluation is possible.

The task

For more extensive analysis requirements, a supplemental system should be developed that permits individual adaptation of the analyses and new views of the results. Another key requirement was that it must also be possible for the development engineers to carry out the evaluations from the office independently of the test bench.

Our solution

The desired expansions and modifications were realized with the measX software X-Frame. Individual solutions can be realized especially efficiently with X-Frame: Components and functions that are required in every application are already present and only need to be parameterized or adapted for the respective task.

Additional analysis options

In the first phase, the analysis operation was created. This included integration of the test-bench-specific SEF file format in DIAdem, creation of a user application (data navigation, selection and parameterization of the evaluation) and realization of the actual evaluation in the form of calculation formulas and layouts. The new presentation of the results provides not only the characteristic curves but also additional characteristic values, including automatic variance comparison with corresponding visualization. The transformation of the force-distance graphs into force-speed graphs is now also possible. Analysis results for multiple shock absorbers can be compared with each other in all diagrams.

Central data storage

The test bench was connected to a central test database designed according to the ASAM-ODS-5 standard. Because the test bench itself produces only proprietary file formats (SEF files), the analysis software was adapted for this (software adapter for reading the SEF files, data storage in the ASAM-ODS-5 database).

In addition, the analysis system was integrated into the customer IT landscape by means of what is called the ZEUS bus. This is an implementation of the ASAM-CCC concepts for distribution of data and applications and their communication over a virtual bus system that has been adapted to the needs of Audi.

The test order system was also connected to the database; the order data is utilized for configuration of the test machine and performance of the tests. All order data can now also be utilized for the evaluations and the subsequent reporting.

In practical use

The engineers have at their disposal a test environment in which test orders and test results can be efficiently managed and processed. All measurement and result data from the test bench as well as the test orders themselves are saved centrally in a database. This data can also be accessed independently of the test bench in order to carry out further evaluations.

For simple and complex calculations as well as comparative evaluations, the users can make use of an extensive library of individual formulas and report layouts, which can be flexibly adapted and expanded.